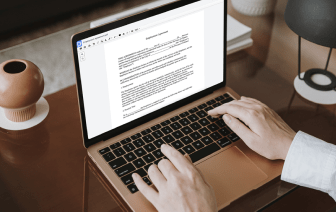

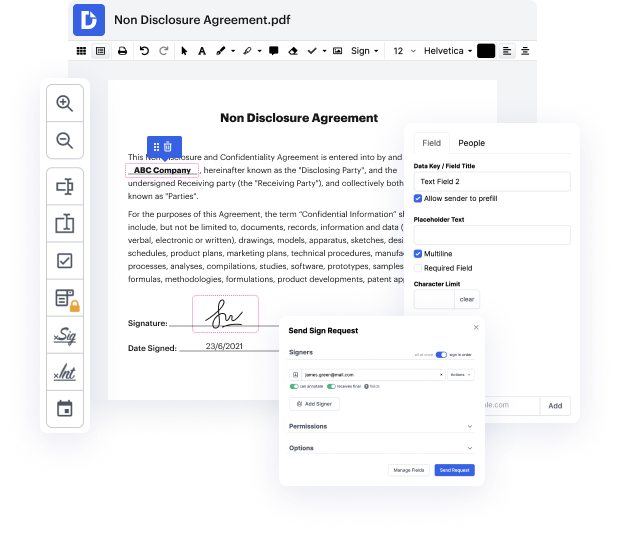

With DocHub, you can quickly inject marking in 600 from any place. Enjoy capabilities like drag and drop fields, editable text, images, and comments. You can collect eSignatures safely, add an extra layer of protection with an Encrypted Folder, and work together with teammates in real-time through your DocHub account. Make changes to your 600 files online without downloading, scanning, printing or mailing anything.

You can find your edited record in the Documents folder of your account. Manage, email, print out, or turn your document into a reusable template. Considering the variety of advanced tools, it’s simple to enjoy seamless document editing and managing with DocHub.

all right welcome back everybody today we are doing another how-to for uncle mark today is going to be the the famous how to an oil injection on these IQ our access our snowmobiles from Polaris as you can see here we have the oil pump we got the tank various lines the lines wonamp;#39;t come pre-cut theyamp;#39;ll come in a spool we get our t cable a couple of clamps the stuff youamp;#39;re gonna get from mark on this is going to be all genuine OEM Polaris parts the tank comes from US plastics but the rest is all genuine Polaris parts tools needed weamp;#39;re going to need pliers five mil Allen ten mil wrench and a knife to cut your line letamp;#39;s get started first weamp;#39;re going to take off this cover a couple 5ml Allen bolts buzz them right out toss the cover aside hang on to the bolts youamp;#39;re gonna need those and here is the pump weamp;#39;re gonna want to line up this with the driver keys right on in and replace the two bolts you just took out probably wouldn