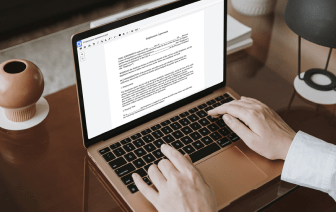

Whether you are already used to working with NB or managing this format for the first time, editing it should not feel like a challenge. Different formats might require specific apps to open and modify them properly. Yet, if you have to swiftly finish symbol in NB as a part of your usual process, it is advisable to find a document multitool that allows for all types of such operations without additional effort.

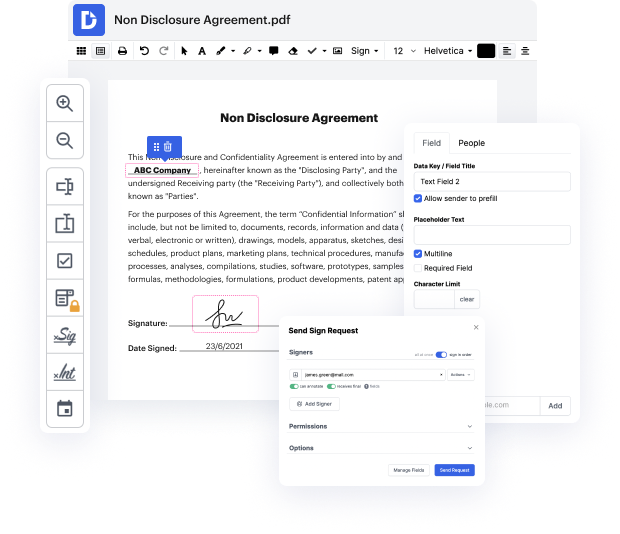

Try DocHub for sleek editing of NB and other document formats. Our platform provides effortless papers processing no matter how much or little previous experience you have. With all tools you need to work in any format, you won’t have to jump between editing windows when working with every one of your files. Effortlessly create, edit, annotate and share your documents to save time on minor editing tasks. You’ll just need to sign up a new DocHub account, and then you can begin your work immediately.

See an improvement in document processing efficiency with DocHub’s simple feature set. Edit any document quickly and easily, irrespective of its format. Enjoy all the benefits that come from our platform’s simplicity and convenience.

surface finish symbols explained this is a little bit lengthy of a video its approximately 18 minutes all of the information that youre going to need to write your cfq that pertains to surface finish is contained within this video please take a moment to like and subscribe its free and itll help me out if you got this symbol on a drawing would you know what it means well by the end of this video you absolutely will know what it means and i will go through this step by step at the end of the video okay lets get started right now warning viewer discretion is advised this video is made for apprentices and may contain scenes that are over explained and may not be appropriate for your skill level before we get started into what all the symbols mean we have to know what were actually measuring we are going to go through and discuss each measurement name and parameter roughness width is basically spacing of repetitive surface irregularities so in other words the tooling marks that your