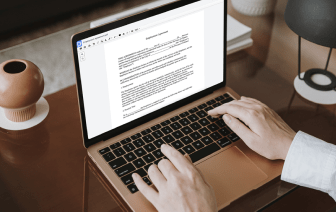

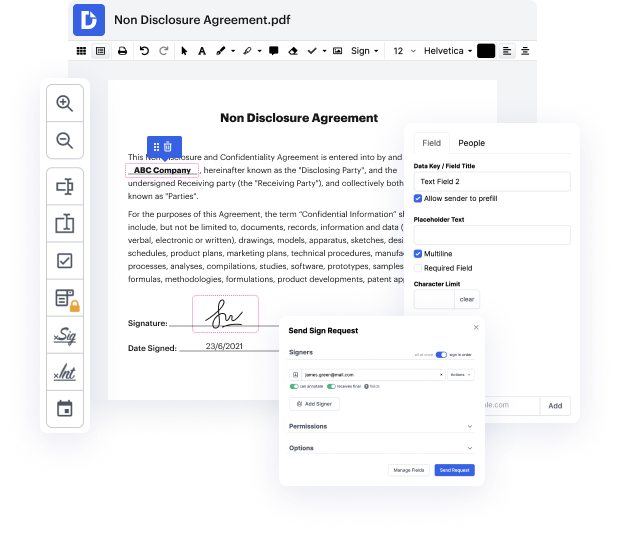

Whether you work with papers daily or only occasionally need them, DocHub is here to assist you take full advantage of your document-based projects. This tool can finish chart in Quality Incident Record, facilitate user collaboration and generate fillable forms and valid eSignatures. And even better, every record is kept safe with the highest security standards.

With DocHub, you can access these features from any location and using any device.

Welcome. In this tutorial we will be constructing control charts for proportions, otherwise known as the p-chart. The p-chart is used to monitor attributes and applies to categorical or qualitative variables. They are generally used to analyze the proportions of non-conforming or defective items in a process. The centreline for the p-chart is p-bar which is found by taking the total of defective or non-conforming items and dividing it by the total number of items sampled. The upper control limit, UCL, is p-bar + 3 times square root of p-bar times q-bar divided by n-bar. The lower control limit, LCL, is similar with a minus sign. q-bar is 1 minus p-bar. That is, proportion of non-defective items. And n-bar is the average of the sample sizes. For our first example, we consider these process data consisting of the number of defective items in a sample of 200 items collected every day for 15 days. We want to calculate the control limits and determine if the process is in statistical contro