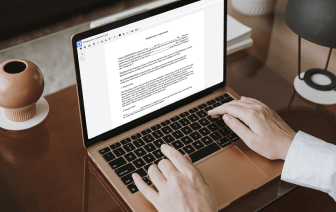

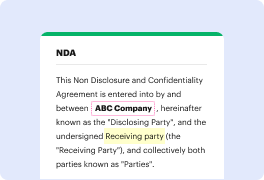

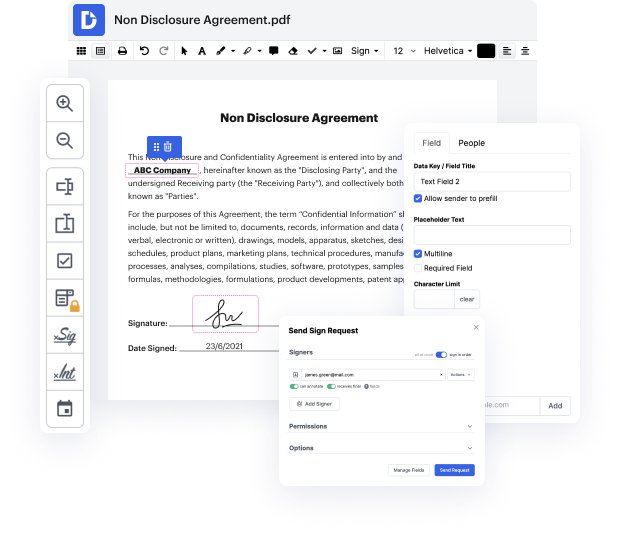

scii may not always be the best with which to work. Even though many editing capabilities are out there, not all offer a simple solution. We developed DocHub to make editing effortless, no matter the document format. With DocHub, you can quickly and easily fill in label in scii. Additionally, DocHub gives an array of other functionality including document generation, automation and management, sector-compliant eSignature solutions, and integrations.

DocHub also lets you save effort by creating document templates from paperwork that you utilize frequently. Additionally, you can take advantage of our a wide range of integrations that enable you to connect our editor to your most used applications easily. Such a solution makes it quick and easy to deal with your files without any slowdowns.

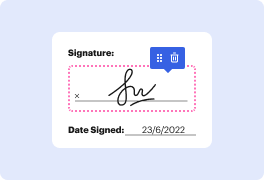

DocHub is a helpful tool for individual and corporate use. Not only does it offer a comprehensive set of capabilities for document creation and editing, and eSignature implementation, but it also has an array of capabilities that come in handy for creating multi-level and straightforward workflows. Anything imported to our editor is stored risk-free according to major industry criteria that protect users' information.

Make DocHub your go-to choice and streamline your document-centered workflows easily!

hi iamp;#39;m rick with all fill labeling and today weamp;#39;re going to go over one of the standard alarm features on our labeler this feature is the feed error the feed error is exactly as the name implies itamp;#39;s an error in the feeding of the label in the most basic terms our labeling head is simply a stepping motor connected to a product sensor and the label sensor the product sensor triggers a label to feed while the label center triggers a label to stop so if you tell the label to feed or the labeling head to feed five inches of material and the stepping motor turns on and does not feed the five inches of material youamp;#39;re going to get the feed error the most common reason for that is the label sensor itself if the label sensor is not set up to see the gap in between the labels this most often happens when a customer changes label material not all the time but there are times when you change label material that you need to reset the sensitivity of the label sensor