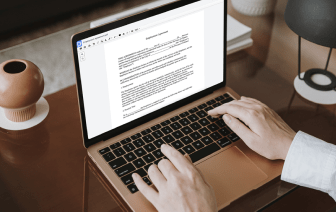

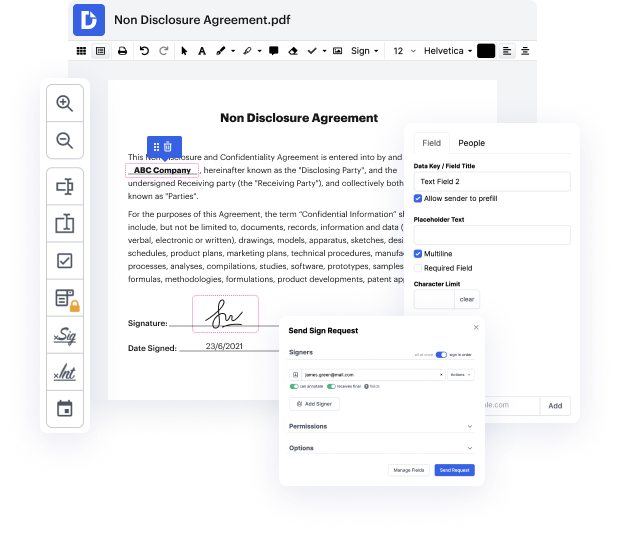

UOF may not always be the easiest with which to work. Even though many editing tools are out there, not all provide a straightforward solution. We designed DocHub to make editing straightforward, no matter the form format. With DocHub, you can quickly and effortlessly fill in dent in UOF. In addition to that, DocHub delivers an array of other functionality such as document generation, automation and management, sector-compliant eSignature services, and integrations.

DocHub also lets you save time by producing document templates from paperwork that you utilize frequently. In addition to that, you can take advantage of our a wide range of integrations that enable you to connect our editor to your most used applications easily. Such a solution makes it fast and simple to deal with your documents without any delays.

DocHub is a helpful feature for individual and corporate use. Not only does it provide a all-purpose set of capabilities for document creation and editing, and eSignature integration, but it also has an array of tools that prove useful for creating multi-level and streamlined workflows. Anything uploaded to our editor is stored safe in accordance with major field criteria that safeguard users' data.

Make DocHub your go-to option and simplify your document-based workflows easily!

in this demonstration Iamp;#39;m going to talk about how to steam pop dents out of a floor my setup is real simple what I have here is an iron any household iron will do I have a knife in case is such as this itamp;#39;s not raw wood I have to poke through the Finish to get the water inside the wood I have my water supply and then I have Rags which I can tear up to different sizes depending on what the size of the dent is so the first thing to do is to be able to get the water into the wood is to put holes into the wood material and you poke into the wood grain pattern just enough to get past the clear coat now you only need to put enough Nicks in the Finish to make sure you have water penetration where the dent is again you donamp;#39;t want to make them too deep because you want them to look much like the poorest part of the wood grain that you see here in this Walnut Oak has porous grain the most difficult Woods to do this would be Maple or cherry because they donamp;#39