Working with paperwork implies making minor modifications to them every day. At times, the task runs nearly automatically, especially when it is part of your everyday routine. Nevertheless, sometimes, working with an unusual document like a Inventory Checklist may take precious working time just to carry out the research. To make sure that every operation with your paperwork is easy and swift, you should find an optimal modifying tool for such tasks.

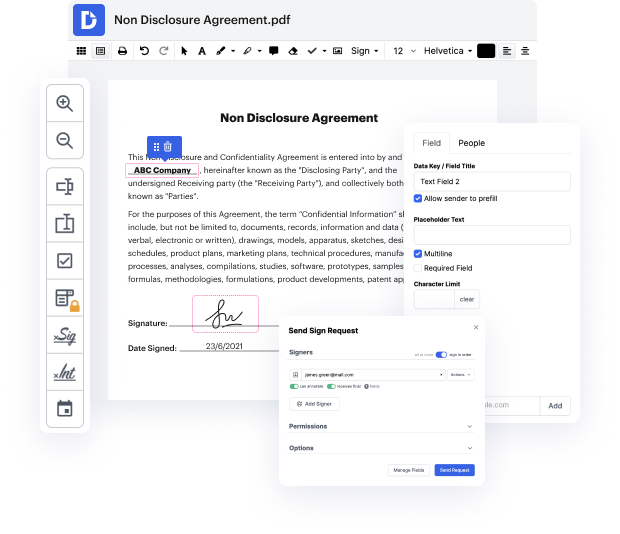

With DocHub, you can see how it works without taking time to figure everything out. Your instruments are laid out before your eyes and are easy to access. This online tool will not require any specific background - training or experience - from the users. It is all set for work even when you are not familiar with software traditionally used to produce Inventory Checklist. Quickly create, modify, and send out documents, whether you deal with them daily or are opening a brand new document type for the first time. It takes minutes to find a way to work with Inventory Checklist.

With DocHub, there is no need to research different document types to figure out how to modify them. Have the essential tools for modifying paperwork at your fingertips to improve your document management.

Tuesday morning has a unique distribution challenge the company is one of the countrys largest closeout and overstock retailers with nearly 700 stores in 45 states it purchases its department store quality merchandise directly from manufacturers and since they are over stocks they usually contain very limited quantities this means that Tuesday morning must acquire a very large number of SKUs to fill its many stores over 100,000 different SKUs are processed each year at its Dallas distribution center and most will never be seen again once they ship to stores such a mix of products will put a strain on any distribution network most retailers replenish their stores by picking products from fixed storage locations but due to the small quantities available of each SKU at Tuesday morning this typical fulfillment design is not practical since each SKU spent so little time in the facility seeing the need to meet a 15% annual growth rate and desiring to be more efficient in processing its eve

At DocHub, your data security is our priority. We follow HIPAA, SOC2, GDPR, and other standards, so you can work on your documents with confidence.

Learn more