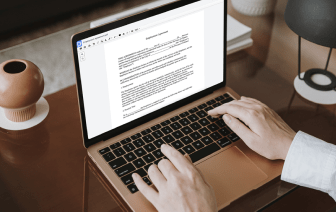

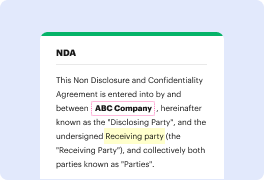

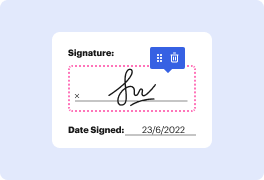

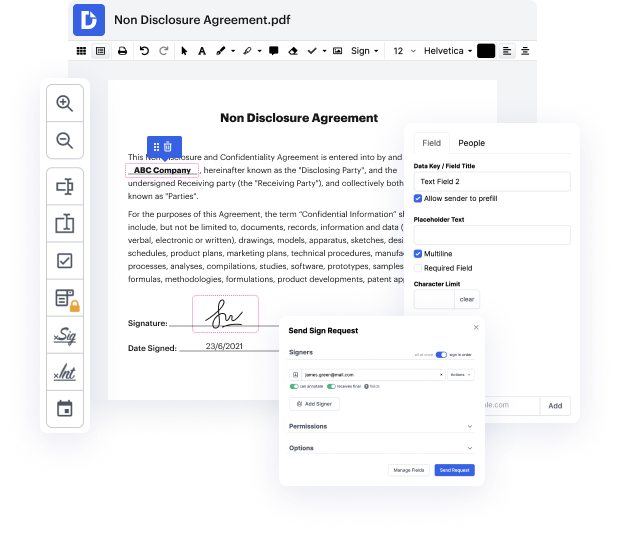

WRF may not always be the best with which to work. Even though many editing capabilities are available on the market, not all offer a straightforward solution. We created DocHub to make editing straightforward, no matter the document format. With DocHub, you can quickly and effortlessly cut signatory in WRF. Additionally, DocHub gives an array of additional tools such as document creation, automation and management, field-compliant eSignature solutions, and integrations.

DocHub also allows you to save effort by creating document templates from documents that you utilize regularly. Additionally, you can make the most of our numerous integrations that allow you to connect our editor to your most used apps easily. Such a solution makes it fast and simple to work with your files without any slowdowns.

DocHub is a useful tool for individual and corporate use. Not only does it offer a all-purpose collection of features for document creation and editing, and eSignature implementation, but it also has an array of capabilities that prove useful for creating multi-level and straightforward workflows. Anything imported to our editor is kept safe according to leading industry requirements that safeguard users' data.

Make DocHub your go-to choice and simplify your document-based workflows easily!

hello my name is rob sandstrom today weamp;#39;re going to cover a process of how you would cut something thatamp;#39;s longer than your cnc bed that process is called tiling and we can do that in the vectric vcarve pro software very easily and straightforward so as an example we have this sign which is 48 inches long the iq cnc bed is only 36 inches long so to be able to cut this sign we need to be able to set up a process where we can cut part of the sign once and then cut the rest of the sign down the road and pull it through thatamp;#39;s called tiling so today weamp;#39;ll cover that in the software how you design the sign or project that you want to cut thatamp;#39;s longer how we design that project so it can be cut along with what weamp;#39;ll call alignment methodologies like an alignment hole is what weamp;#39;re going to use today and then weamp;#39;ll go into actually cutting the material after we cover that in the software with that backdrop letamp;#39;s g