When you deal with diverse document types like Work Completion Record, you are aware how important accuracy and attention to detail are. This document type has its particular format, so it is essential to save it with the formatting intact. For this reason, working with this kind of documents can be quite a challenge for conventional text editing software: one wrong action might ruin the format and take extra time to bring it back to normal.

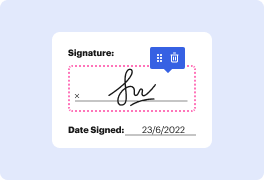

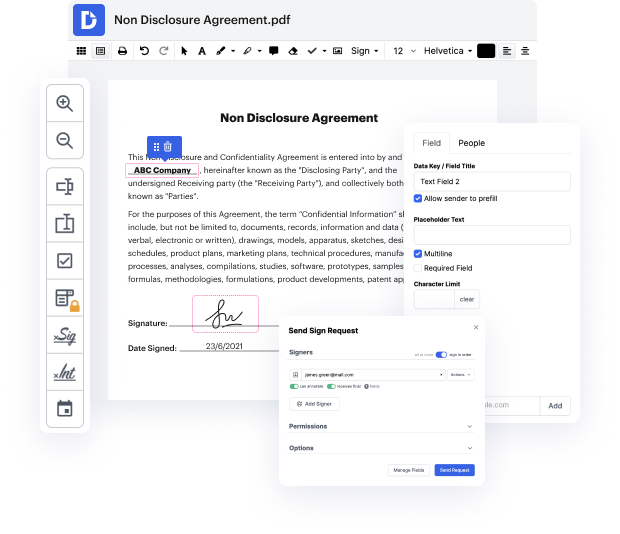

If you wish to cut point in Work Completion Record with no confusion, DocHub is a perfect instrument for such tasks. Our online editing platform simplifies the process for any action you might need to do with Work Completion Record. The streamlined interface design is suitable for any user, whether that individual is used to working with such software or has only opened it for the first time. Access all editing tools you need easily and save your time on daily editing activities. You just need a DocHub profile.

See how straightforward papers editing can be irrespective of the document type on your hands. Access all top-notch editing features and enjoy streamlining your work on paperwork. Sign up your free account now and see instant improvements in your editing experience.

so youve put a ton of work into your life part and its time for the part off even though this could be the last step it is one of the most important and doing it incorrectly could ruin all your hard work and your tooling today im going to show you a few tips and tricks on the best way to use the croft tools and how to use haastooling.com to pick up the right tool for the job parting off is the most efficient and productive way to separate machine parts from raw materials so completed parts can be ejected into a parts catcher or partially completed parts can be transferred to a sub spindle so here are the cutoff components available on haas tooling blocks blades and inserts we have three sizes of cutoff blocks then we have three different widths of inserts to select from two millimeter three millimeter or four millimeter there are also three blades each blade is made with different seat sizes and whips to accommodate the corresponding inserts this means the blades and inserts are no

At DocHub, your data security is our priority. We follow HIPAA, SOC2, GDPR, and other standards, so you can work on your documents with confidence.

Learn more