Not all formats, such as INFO, are designed to be easily edited. Even though many features will let us edit all form formats, no one has yet created an actual all-size-fits-all solution.

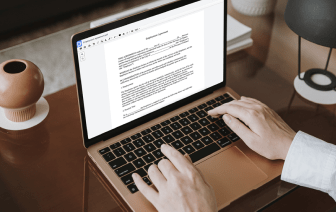

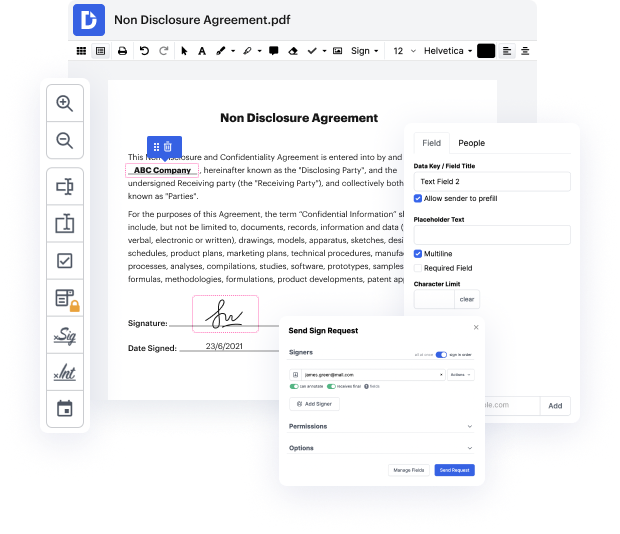

DocHub offers a simple and streamlined solution for editing, managing, and storing papers in the most widely used formats. You don't have to be a technology-savvy user to cut off typesetting in INFO or make other changes. DocHub is robust enough to make the process straightforward for everyone.

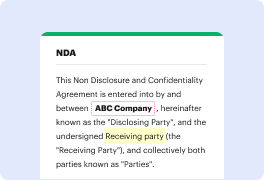

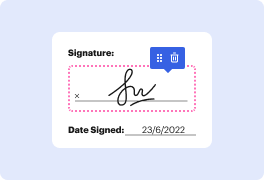

Our feature enables you to alter and edit papers, send data back and forth, create dynamic documents for information collection, encrypt and protect documents, and set up eSignature workflows. Additionally, you can also create templates from papers you utilize on a regular basis.

You’ll find plenty of other features inside DocHub, including integrations that allow you to link your INFO form to various productivity programs.

DocHub is a straightforward, fairly priced way to handle papers and streamline workflows. It provides a wide array of tools, from creation to editing, eSignature professional services, and web form building. The software can export your files in multiple formats while maintaining greatest security and adhering to the maximum information protection requirements.

Give DocHub a go and see just how straightforward your editing transaction can be.

welcome to this practical demonstration on cutting we are going to discuss the different cutting methods the parameters used for cutting and a few practical tips for optimal cutting before we get into that I just want to explain the difference between manual and automatic cutting briefly when cutting manually the operator controls the speed of the cuts by pulling the handle when cutting automatically itamp;#39;s the machine that drives the specimen into the cutoff wheel this ensures a steadier pace automatic cutting ensures more reproducible results because the operator influence is eliminated it is not possible to cut as slowly and controlled from cutting manually as it is when cutting automatically the first parameter I would like to discuss is the feed speed the feed speed is the speed with which that wheel cuts into the workpiece this results in a force at the contact point between the wheel and workpiece the specific pressure or the force per area will be constant through