Disadvantages exist in every solution for editing every document type, and even though you can find a wide variety of tools out there, not all of them will fit your specific requirements. DocHub makes it easier than ever to make and modify, and handle documents - and not just in PDF format.

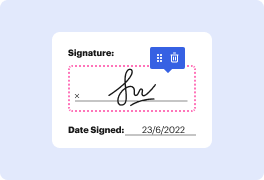

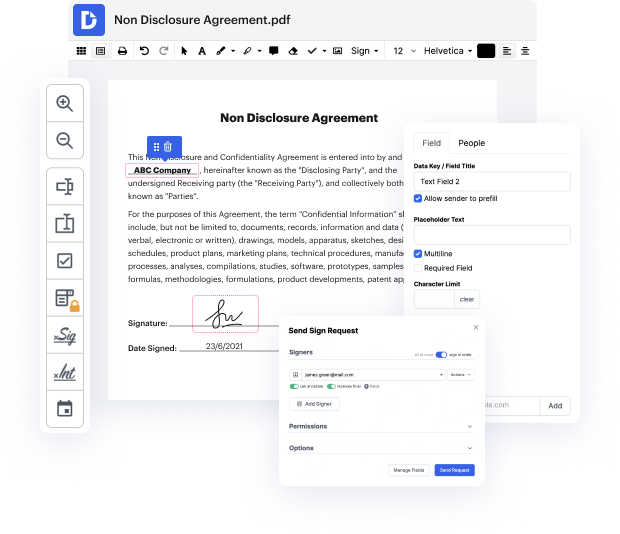

Every time you need to swiftly cut off typesetting in ASC, DocHub has got you covered. You can effortlessly alter form elements such as text and images, and structure. Customize, organize, and encrypt documents, develop eSignature workflows, make fillable forms for smooth data collection, and more. Our templates feature allows you to create templates based on documents with which you frequently work.

Moreover, you can stay connected to your go-to productivity tools and CRM solutions while handling your documents.

One of the most remarkable things about using DocHub is the option to deal with form tasks of any difficulty, regardless of whether you need a swift modify or more complex editing. It includes an all-in-one form editor, website document builder, and workflow-centered tools. Moreover, you can be sure that your documents will be legally binding and comply with all security frameworks.

Shave some time off your projects with DocHub's tools that make managing documents easy.

when you first open v carve youamp;#39;ll need to create a new file up here here weamp;#39;ll set our width to typically 48 inches and our height to 96 inches and the X and the y because thatamp;#39;s a 4x8 sheet of plywood and weamp;#39;ll usually set our 0 to be at the top of the sheet our thickness of this piece that weamp;#39;re gonna be using is 3/4 of an inch because itamp;#39;s 3/4 nominal however itamp;#39;s not actually 0.75 inches three-quarter nominal plywood is actually only 23 30 seconds which ends up to be about 0.72 inches thick weamp;#39;re not normally going to use an offset weamp;#39;re gonna put our 0 0 down here in the lower left corner as you can see there however if we do want to use an offset we could type in something like 6 6 and you can see now that our 0 0 is here and our piece is actually here now of course we canamp;#39;t put a 4x8 sheet of plywood on the machine at this point with a 6 6 offset so weamp;#39;d have to change our dimensions but we