Not all formats, such as PAP, are designed to be quickly edited. Even though many capabilities will let us modify all document formats, no one has yet invented an actual all-size-fits-all tool.

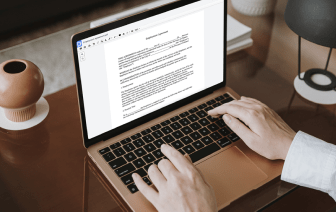

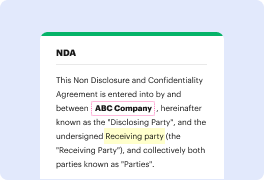

DocHub gives a easy and streamlined tool for editing, handling, and storing papers in the most popular formats. You don't have to be a technology-savvy person to cut off print in PAP or make other modifications. DocHub is robust enough to make the process easy for everyone.

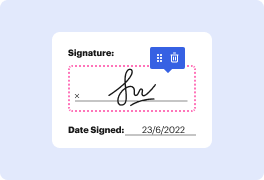

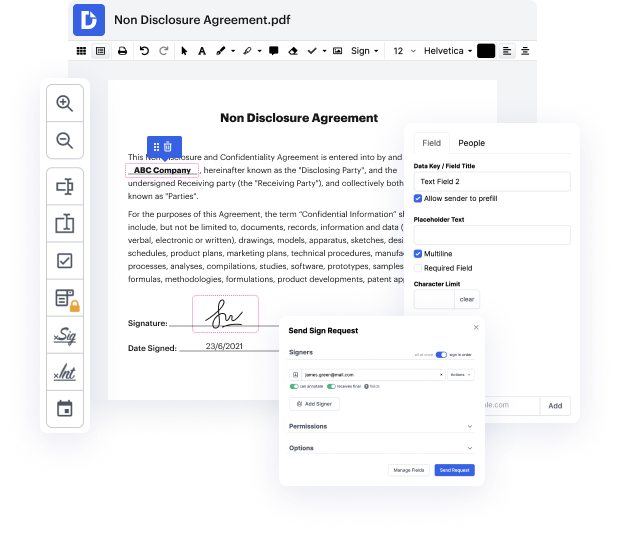

Our feature allows you to modify and tweak papers, send data back and forth, generate interactive documents for data gathering, encrypt and protect documents, and set up eSignature workflows. In addition, you can also generate templates from papers you utilize regularly.

You’ll find a great deal of other features inside DocHub, including integrations that let you link your PAP document to a wide array of productivity programs.

DocHub is an intuitive, cost-effective way to manage papers and simplify workflows. It offers a wide array of capabilities, from generation to editing, eSignature services, and web form developing. The program can export your documents in multiple formats while maintaining maximum safety and adhering to the highest data safety standards.

Give DocHub a go and see just how easy your editing operation can be.

hey welcome to the channel today we have a little different video and what weamp;#39;re going to do is weamp;#39;re going to design and print a part for a CPAP breathing machine I had a friend that dropped it broke the end of it off and his tube doesnamp;#39;t fit in the top of the machine anymore so weamp;#39;re gonna make them a new one weamp;#39;re going to start out by loading solid Edge which is a CAD software and what weamp;#39;re going to do is weamp;#39;re going to start out in making a circle weamp;#39;re going to draw a circle 28.9 centimeters and all these are going to be in centimeters so put in the number and there it is there that will be the bottom of our part so now what we want to do is we want to um extrude or stretch that part and we want to stretch that part to 31.75 centimeters millimeters 975 there it is there thatamp;#39;s the bottom cylinder now we want to build the top cylinder so we want the top cylinder to start there and that cylinder that upper cyl