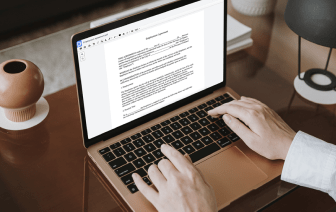

Not all formats, including DITA, are created to be quickly edited. Even though numerous features can help us change all file formats, no one has yet invented an actual all-size-fits-all solution.

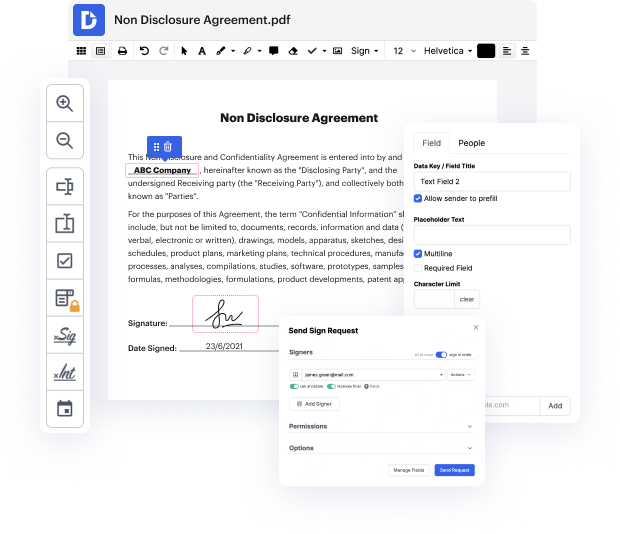

DocHub offers a straightforward and efficient solution for editing, managing, and storing papers in the most widely used formats. You don't have to be a technology-knowledgeable user to cut off print in DITA or make other tweaks. DocHub is robust enough to make the process straightforward for everyone.

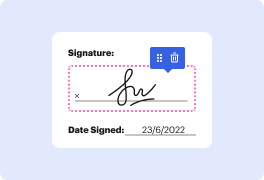

Our feature enables you to alter and tweak papers, send data back and forth, create dynamic forms for data gathering, encrypt and safeguard paperwork, and set up eSignature workflows. Moreover, you can also create templates from papers you utilize on a regular basis.

You’ll locate a great deal of other features inside DocHub, such as integrations that allow you to link your DITA file to various business apps.

DocHub is a simple, cost-effective option to manage papers and improve workflows. It provides a wide selection of capabilities, from generation to editing, eSignature providers, and web form developing. The software can export your paperwork in many formats while maintaining maximum security and adhering to the greatest data protection standards.

Give DocHub a go and see just how straightforward your editing transaction can be.

I printed this part without using support structure hereamp;#39;s how I did it 3D printers need some sort of support surface on which they can place the model material you canamp;#39;t start a print in midair so normally you would have to print this part using support material but that leads to ugly surfaces and wasted material and also it can be a pain to remove so here comes the trick this part was not printed in one pass instead it was once two parts I passed the print at a certain height and inserted the top part I had printed previously the printer then fuses the parts together and since they are exactly the same material the result is a bond that is just as strong as if yet it had been printed directly as one part in fact you can insert many parts into a print magnets or knots are practical but embedding printed Parts with zero tolerance results in great finishes in places that would otherwise be impossible to print with their quality and that is how