Not all formats, including FDX, are designed to be quickly edited. Even though many tools can help us change all form formats, no one has yet created an actual all-size-fits-all tool.

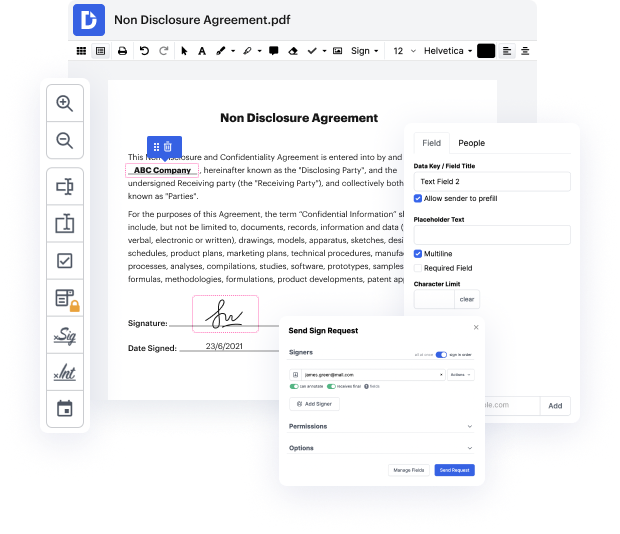

DocHub provides a simple and streamlined tool for editing, taking care of, and storing paperwork in the most popular formats. You don't have to be a tech-knowledgeable user to bold epitaph in FDX or make other changes. DocHub is robust enough to make the process straightforward for everyone.

Our feature enables you to modify and tweak paperwork, send data back and forth, generate dynamic documents for information gathering, encrypt and shield paperwork, and set up eSignature workflows. Additionally, you can also generate templates from paperwork you use regularly.

You’ll find a great deal of other functionality inside DocHub, including integrations that allow you to link your FDX form to various productivity programs.

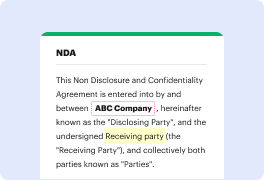

DocHub is a straightforward, cost-effective way to deal with paperwork and improve workflows. It provides a wide range of capabilities, from generation to editing, eSignature providers, and web form building. The application can export your documents in many formats while maintaining maximum protection and adhering to the highest information protection criteria.

Give DocHub a go and see just how straightforward your editing transaction can be.

to adjust your parallel blade start by loosening the break knobs on the sides as far as they will go you can then gently lift your parallel blade and move it to desired position and retighten the break knobs tightly there may be times when you tape a project to the board and find that the existing lines arenamp;#39;t exactly parallel to your straightedge instead of pulling the project often retaping it you can fine tuning the straightedge to be more parallel with the lines to do so start by releasing the brake knobs on the side and loosing but donamp;#39;t completely unscrew the fine-tune parallel knob on the top of the straightedge adjust the end bracket until the straightedge is parallel with your work this is for fine-tuning only and the blade wonamp;#39;t move very far if additional fine-tuning is necessary you can repeat the process on the other side