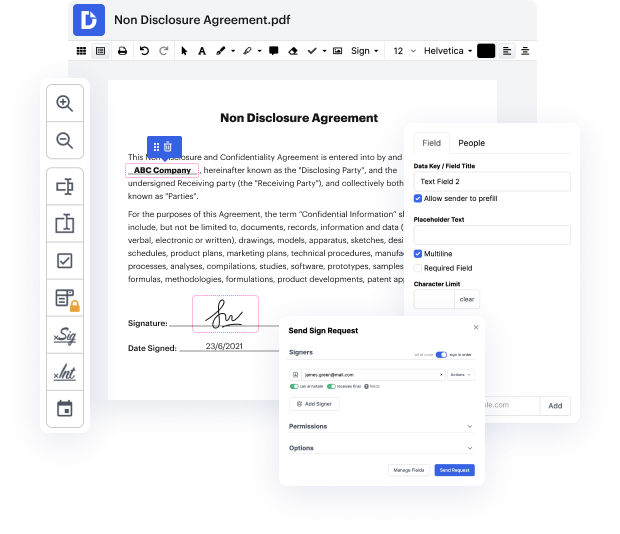

XPS may not always be the best with which to work. Even though many editing capabilities are available on the market, not all offer a straightforward solution. We designed DocHub to make editing easy, no matter the form format. With DocHub, you can quickly and effortlessly blot out city in XPS. In addition to that, DocHub provides a variety of other functionality such as form creation, automation and management, industry-compliant eSignature solutions, and integrations.

DocHub also enables you to save time by creating form templates from paperwork that you utilize regularly. In addition to that, you can take advantage of our numerous integrations that enable you to connect our editor to your most used apps with ease. Such a solution makes it fast and simple to work with your files without any delays.

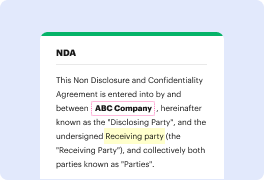

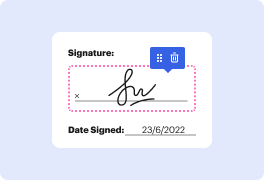

DocHub is a handy feature for individual and corporate use. Not only does it offer a comprehensive set of features for form creation and editing, and eSignature integration, but it also has a variety of capabilities that come in handy for producing multi-level and streamlined workflows. Anything added to our editor is kept safe according to leading industry criteria that protect users' data.

Make DocHub your go-to choice and simplify your form-based workflows with ease!

eps xps and polyiso three very similar forms of board insulation used in home construction and in the building construction industry in general in todayamp;#39;s video weamp;#39;re going to look into how they are made and compare their physical and chemical properties letamp;#39;s start with eps or expanded polystyrene the monomer styrene is composed of a benzene ring c6h6 and ethylene they are both made by the petrochemical industry under heat or by an initiator like benzoyl peroxide the double bond between the carbon atoms is converted into a single bond and a polymer chain called polystyrene is formed this liquid polystyrene is dropped in water to form droplets or beads this video shows how polystyrene pellets expand in the presence of steam commercially the polystyrene beads are expanded with blowing agents such as propane pentane and methylene chloride the eps beads are contained in a mold and then heat or steam is applied to it which causes the small beads to expand and fuse t