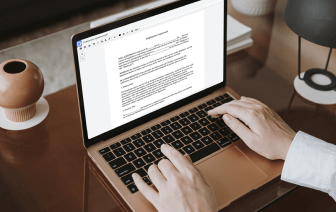

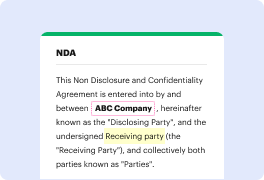

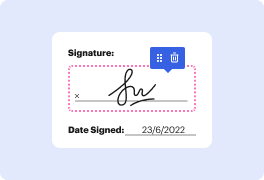

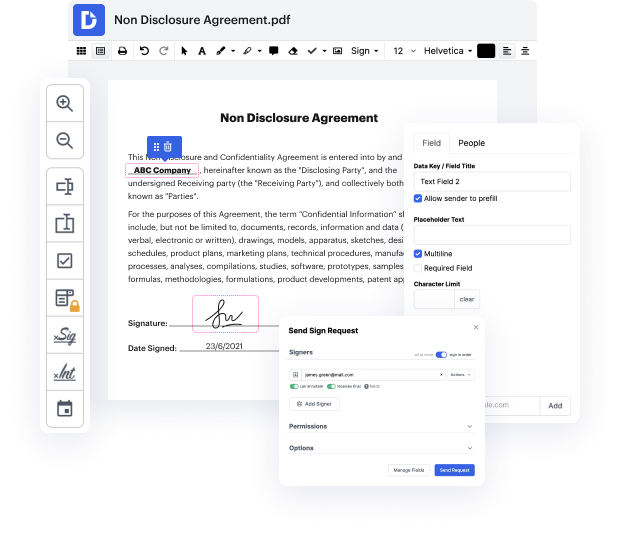

If you want to apply a minor tweak to the document, it must not take long to Assemble line paper. This type of basic activity does not have to require extra training or running through handbooks to understand it. Using the appropriate document modifying instrument, you will not take more time than is necessary for such a swift change. Use DocHub to streamline your modifying process whether you are an experienced user or if it’s your first time using a web-based editor service. This instrument will require minutes or so to figure out how to Assemble line paper. The only thing needed to get more productive with editing is actually a DocHub account.

A plain document editor like DocHub will help you optimize the amount of time you need to spend on document modifying no matter your prior experience with this kind of instruments. Create an account now and increase your productivity immediately with DocHub!

Today's lean tip is a clip from the introduction to lean manufacturing mini-course available on the website LeanSmarts.com. The clip focuses on methods of lean production, specifically converting batch production into one-piece flow. This transformation can result in over 50% improvement in efficiency. The video features two employees demonstrating the process, showcasing the benefits of one-piece flow. Watch the clip to see the concept in action and its amazing results.