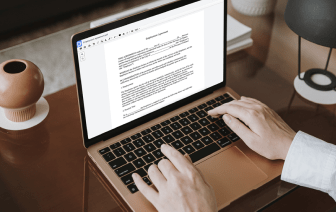

When your everyday tasks scope includes lots of document editing, you already know that every file format requires its own approach and often particular applications. Handling a seemingly simple FTM file can often grind the whole process to a halt, especially when you are attempting to edit with insufficient tools. To avoid such troubles, get an editor that can cover your requirements regardless of the file format and add company in FTM with zero roadblocks.

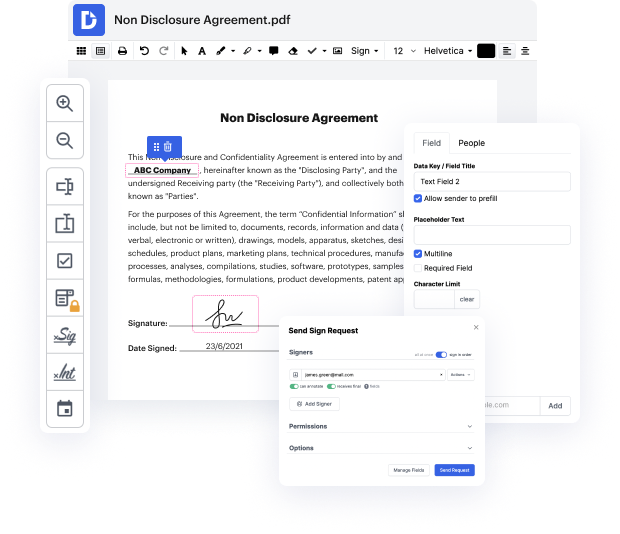

With DocHub, you are going to work with an editing multitool for just about any situation or file type. Minimize the time you used to invest in navigating your old software’s features and learn from our intuitive interface design while you do the work. DocHub is a sleek online editing platform that covers all of your file processing requirements for any file, such as FTM. Open it and go straight to productivity; no previous training or reading guides is needed to reap the benefits DocHub brings to papers management processing. Start with taking a few minutes to register your account now.

See improvements within your papers processing just after you open your DocHub profile. Save your time on editing with our one solution that will help you be more efficient with any document format with which you have to work.

the TP 60p cleaning robot allow the precise monitoring of settings while doing flexing d Goulding and cleaning operations the robot includes a control box a component carrier shall be used to end of the path to process this carrier should be designed and fitted to the components for instance round square collectors hybrid components and so on the carrier loader can be used to ease the positioning of the path a fraction crucible using a pantograph device complete installation and of course you will need at inning bath 300 times 50 or 200 Stein 90 this video shows the different steps of the process first the installation of the components on the career using a loader the flexing operations can be handled manually or with a pantograph the settings of the TP 60p allowed to monitor piece Ive the four parameters the preheating time the entrance speed in the bath the emotion time the exit speed then adjusting the angle of the component on the carrier we can perform cleaning operations avoid