Start by setting up a free DocHub account using any offered sign-up method. Just log in if you already have one.

Try out the whole collection of DocHub's advanced tools by signing up for a free 30-day trial of the Pro plan and proceed to craft your US Insulation Contractor Form.

In your dashboard, choose the New Document button > scroll down and hit Create Blank Document. You’ll be taken to the editor.

Utilize the Page Controls icon indicated by the arrow to switch between different page views and layouts for more convenience.

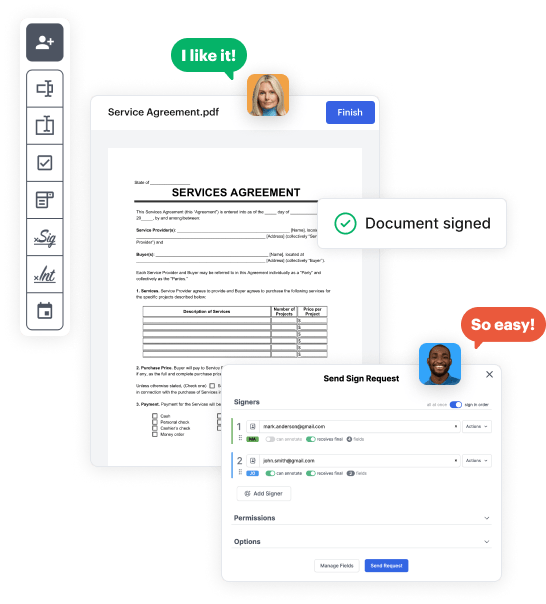

Navigate through the top toolbar to place document fields. Insert and configure text boxes, the signature block (if applicable), add photos, and other elements.

Arrange the fillable areas you incorporated per your chosen layout. Customize the size, font, and alignment to make sure the form is user-friendly and neat-looking.

Save the completed copy in DocHub or in platforms like Google Drive or Dropbox, or create a new US Insulation Contractor Form. Send out your form via email or get a public link to engage with more people.