When your day-to-day tasks scope includes plenty of document editing, you already know that every document format requires its own approach and sometimes particular software. Handling a seemingly simple CCF file can often grind the whole process to a stop, especially if you are trying to edit with inadequate software. To avoid this kind of problems, get an editor that can cover all your needs regardless of the file format and void watermark in CCF without roadblocks.

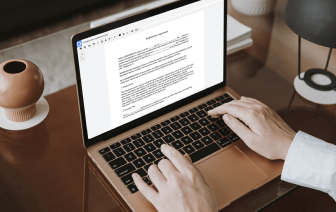

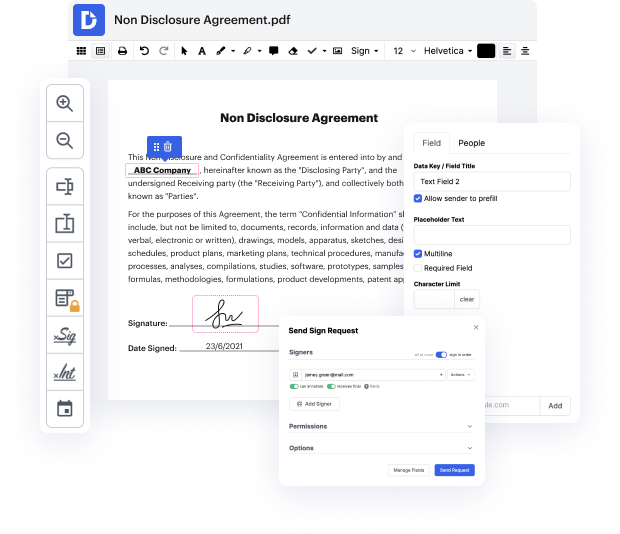

With DocHub, you are going to work with an editing multitool for any situation or document type. Reduce the time you used to devote to navigating your old software’s functionality and learn from our intuitive interface design while you do the job. DocHub is a sleek online editing platform that covers all your document processing needs for virtually any file, including CCF. Open it and go straight to productivity; no previous training or reading guides is needed to enjoy the benefits DocHub brings to document management processing. Start with taking a few minutes to register your account now.

See upgrades in your document processing immediately after you open your DocHub account. Save time on editing with our single platform that can help you be more productive with any document format with which you need to work.

hello today youre looking at a jwi 120g continuous belt sludge driver brought to you by lanco overall Dimension 78 inches tall by 160 inches long by 60 inches wide come over here at the control panel unit has been fully refurbished is in very good working condition unit is wired for 240 volt three phase take a look at the name plate if we can read that there [Music] does have a steel Hopper right here and how this works is you would dump your sludge into the hopper on the right but then go up the belt which well look at in a second theres heaters heating down on the Belt drying the sludge as it goes up and that sludge would then fall out the dry sludge would then fall out of the Chute here youd have a hopper or a basket or something along those lines inside the steel Hopper it is repainted with two-part epoxy on the inside youll see the paddles spinning and that breaks up your sludge smaller pieces the extruder there spinning on the bottom will then Force the sludge down onto the