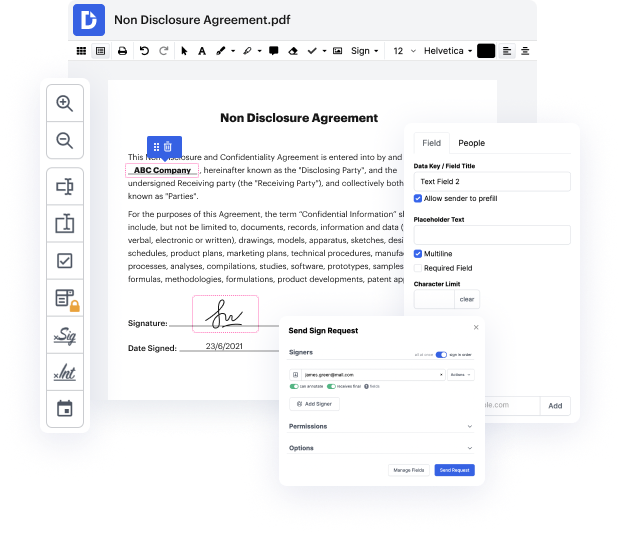

Flaws exist in every solution for editing every file type, and even though you can find many tools on the market, not all of them will fit your specific needs. DocHub makes it easier than ever to make and change, and manage documents - and not just in PDF format.

Every time you need to easily rub out address in TXT, DocHub has got you covered. You can effortlessly modify form elements including text and images, and layout. Customize, arrange, and encrypt documents, build eSignature workflows, make fillable forms for intuitive information collection, and more. Our templates option allows you to create templates based on documents with which you often work.

In addition, you can stay connected to your go-to productivity tools and CRM platforms while dealing with your documents.

One of the most extraordinary things about leveraging DocHub is the ability to deal with form tasks of any difficulty, regardless of whether you need a swift tweak or more complex editing. It includes an all-in-one form editor, website document builder, and workflow-centered tools. In addition, you can rest assured that your documents will be legally binding and abide by all protection protocols.

Cut some time off your tasks with DocHub's capabilities that make handling documents straightforward.

do weamp;#39;re now ready to buff out the guitar body and the neck after wet sanding up to p5000 grit but before we get into the buffing i want to make some introductory comments about buffing and what we did prior in general one of the reasons that we wet sanded up the p5000 grid was to make buffing go easier because in my opinion buffing whether you do it by hand or with a pedestal buffer is one of the trickiest things to learn to do and to learn to do well it also does require a little bit of an investment in materials the other problem with buffing is there is a lot of information about different ways of doing it for example iamp;#39;ve heard of people going from p 800 right to a buffing wheel using a very coarse compound and then working up to the very fine compounds iamp;#39;ve also heard of people going up to only p 1500 which is the way i used to do it and then going to maybe like a medium or a coarse cut cleaner than medium and then fine and then super fine