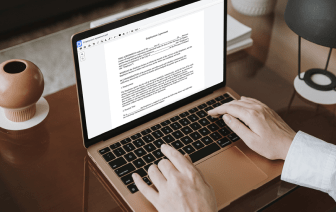

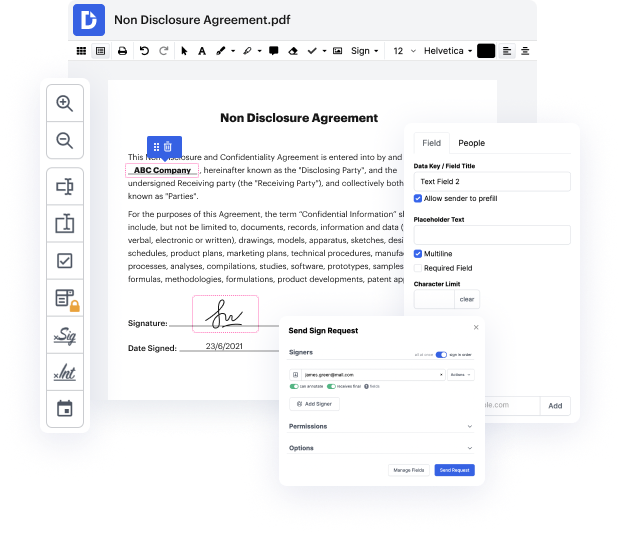

Document generation and approval certainly are a key priority of each business. Whether dealing with large bulks of files or a distinct agreement, you must remain at the top of your productivity. Getting a perfect online platform that tackles your most common record generation and approval challenges might result in quite a lot of work. Numerous online apps offer only a restricted set of modifying and eSignature capabilities, some of which could possibly be useful to deal with ABW file format. A solution that handles any file format and task would be a excellent option when selecting software.

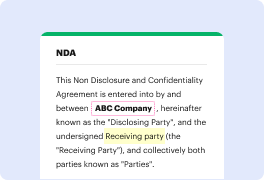

Get file management and generation to a different level of straightforwardness and sophistication without opting for an cumbersome interface or expensive subscription plan. DocHub offers you instruments and features to deal successfully with all file types, including ABW, and carry out tasks of any complexity. Edit, arrange, and produce reusable fillable forms without effort. Get complete freedom and flexibility to paste id in ABW anytime and securely store all of your complete documents in your profile or one of many possible integrated cloud storage apps.

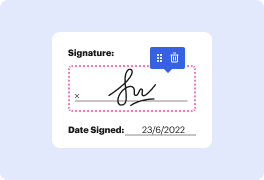

DocHub offers loss-free editing, eSignaturel collection, and ABW management on the expert level. You don’t need to go through tedious guides and invest countless hours finding out the application. Make top-tier secure file editing an ordinary process for your day-to-day workflows.

welcome to the lathe soft jaw video series brought to you by Haas Automation in our first video we learned about the fundamentals of cutting lathe soft jaws when we made two different sets of OD gripping jaws in this second video we are once again joined by Andrew who will now cover the important aspects of id gripping jaws using this ring cap as an example we also cover recutting your jaws as well as how and when to add a taper to jaws to achieve a perfect fit most often id gripping jaws are used to hold parts which must be completely profiled on the outside face of the part or where the OD geometry of the part makes the surface difficult to grip the ID bore and back face of this ring cap were completed while the work piece was OD gripped in the first operation and since we need to machine curved surfaces on the parts outer diameter we need to hold it with internal gripping jaws andrew is considering whether to use standard soft jaws or PI jaws to ID grip this part if he were to use