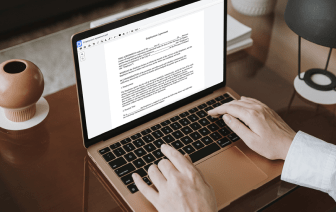

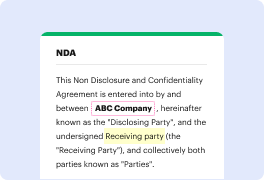

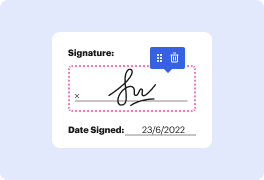

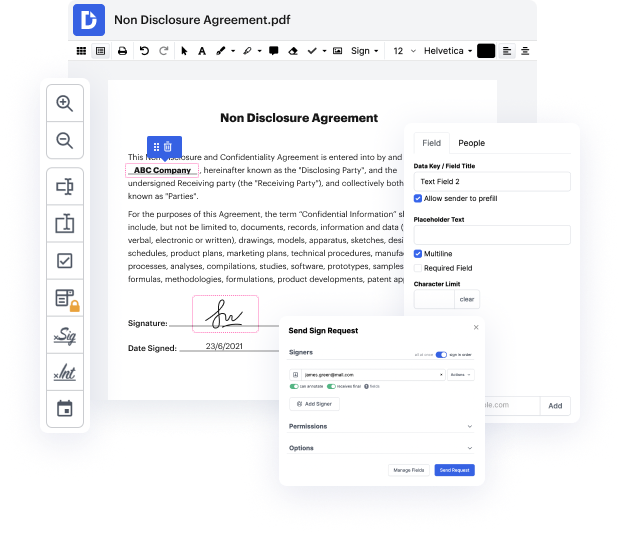

You no longer have to worry about how to modify point in HWPML. Our powerful solution provides simple and quick document management, allowing you to work on HWPML documents in a few moments instead of hours or days. Our platform includes all the features you need: merging, inserting fillable fields, approving documents legally, placing symbols, and so on. There’s no need to install extra software or bother with expensive applications demanding a powerful computer. With only two clicks in your browser, you can access everything you need.

Start now and manage all different types of files like a pro!

hi everyone Marty here with another HSM works quick tip when finishing parts that have previously manufactured features like casts or additive parts probing cycles can shift and rotate the work coordinate system to more accurately match the part however there are some key components to successfully rotating the work coordinate system with a probing operation in the setup the X or Y axis should be aligned to the face I intend to probe the work coordinate system origin needs to be located at the center of any possible rotation locating pins or bores in a fixture plate like the one for this cast gearbox will ensure that the part is rotating around that specific point now to actually adjust the work coordinate system Iamp;#39;ll add a probe operation also flat-faced and change the probe type to why single surface angle clearance and over travel will define how far from the part the probe enters and how far past the expected location it travels these values posts directly into the probe ma