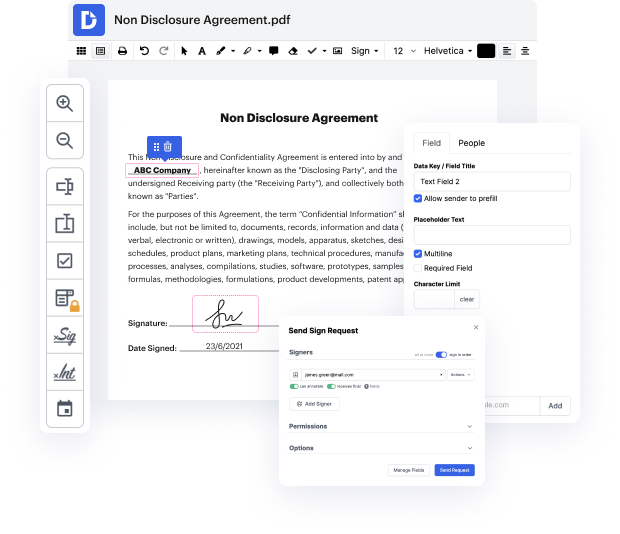

Most companies ignore the key benefits of comprehensive workflow software. Frequently, workflow programs concentrate on one particular aspect of document generation. You can find much better choices for many sectors that require an adaptable approach to their tasks, like Food Storage Inventory preparation. But, it is possible to get a holistic and multi purpose solution that will cover all your needs and demands. As an illustration, DocHub can be your number-one choice for simplified workflows, document generation, and approval.

With DocHub, it is possible to generate documents from scratch by using an extensive set of instruments and features. You are able to quickly link symbol in Food Storage Inventory, add feedback and sticky notes, and track your document’s advancement from start to end. Quickly rotate and reorganize, and blend PDF documents and work with any available formatting. Forget about seeking third-party solutions to cover the most basic demands of document generation and utilize DocHub.

Get complete control over your forms and files at any time and create reusable Food Storage Inventory Templates for the most used documents. Make the most of our Templates to avoid making typical errors with copying and pasting exactly the same info and save time on this cumbersome task.

Streamline all your document procedures with DocHub without breaking a sweat. Uncover all possibilities and capabilities for Food Storage Inventory management right now. Begin your free DocHub profile right now without any concealed fees or commitment.

when we store for example a product like tomatoes that we slice and prepare we put them in the cambro container with the red lid and then if theres a product thats currently on the line the red lid is sitting on top of the container thats in the cooler that way we know that theres product on the line and whats in the container thats in the cooler has not yet the point on the line when we prepare a product like broccoli for example we know that one bag fits into an 8 quart container and so when its washed and prepped it gets put into the container that has the red lid but then its product diminishes while its on the line will sometimes have a smaller lid because the product will fill into a smaller container for example with the green lid for products like meats and cheeses and dairy we use the translucent lids and we do the same procedure that we do for all of the vegetables if theres a product thats on the line the lid stands on top of the other container thats in the cool

At DocHub, your data security is our priority. We follow HIPAA, SOC2, GDPR, and other standards, so you can work on your documents with confidence.

Learn more