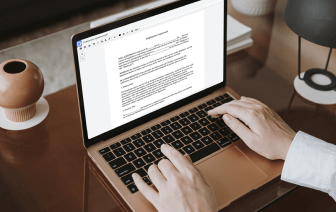

Disadvantages are present in every solution for editing every document type, and despite the fact that you can use a wide variety of tools on the market, not all of them will fit your specific needs. DocHub makes it easier than ever to make and change, and manage documents - and not just in PDF format.

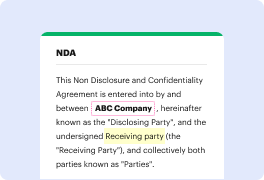

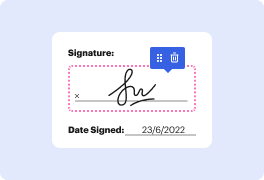

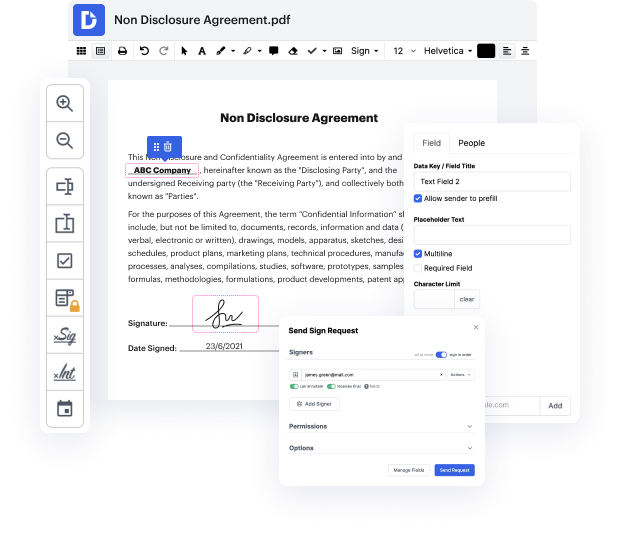

Every time you need to easily inlay type in CWK, DocHub has got you covered. You can quickly modify document elements such as text and images, and layout. Customize, organize, and encrypt files, develop eSignature workflows, make fillable documents for stress-free information collection, and more. Our templates option enables you to create templates based on documents with which you frequently work.

In addition, you can stay connected to your go-to productivity tools and CRM platforms while handling your files.

One of the most incredible things about using DocHub is the ability to manage document tasks of any difficulty, regardless of whether you require a swift modify or more complex editing. It includes an all-in-one document editor, website form builder, and workflow-centered tools. In addition, you can be sure that your documents will be legally binding and comply with all safety protocols.

Shave some time off your tasks by leveraging DocHub's features that make handling files effortless.

hello and welcome to this vbit inlay tutorial in this tutorial weamp;#39;re going to take a look at a few different ways that you can create inlays by using v bits now for the last few weeks iamp;#39;ve been practicing this and trying out a few methods on my machine and this was spurred by a group of guys in the carve cove facebook group who have been doing these and iamp;#39;ve never done one so i was quite curious about actually trying this out so iamp;#39;m using a really small machine so iamp;#39;ve actually set a few limitations for myself which is iamp;#39;m using a really small machine so itamp;#39;s the same smart 3018 machine so quite a small bed size canamp;#39;t take too much of a depth of cut and i canamp;#39;t obviously ramp the cuts up and get it going really really fast also iamp;#39;m using a 90 degree v-bit now it would be easier if i used a 30 degree letamp;#39;s say 15 60 degree whatever now i could have used one of those but i wanted to use a 90 degree be