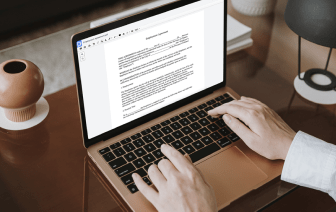

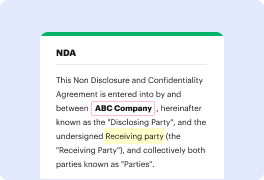

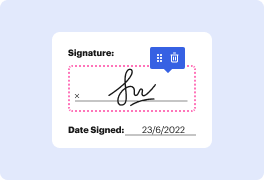

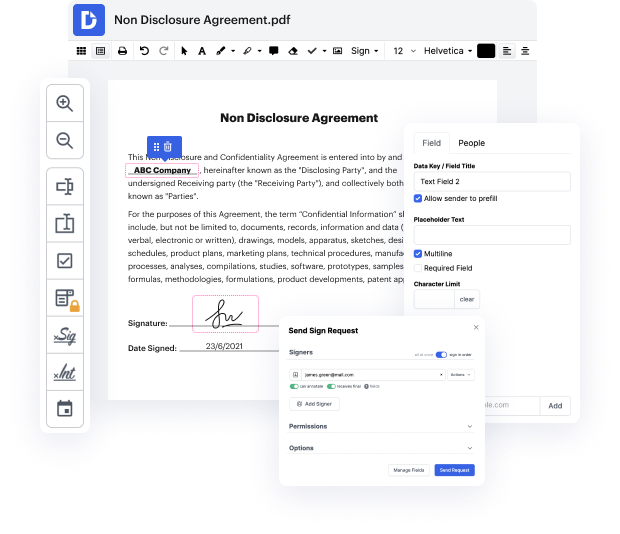

HWP may not always be the simplest with which to work. Even though many editing features are available on the market, not all give a straightforward solution. We created DocHub to make editing easy, no matter the document format. With DocHub, you can quickly and effortlessly inlay personal information in HWP. Additionally, DocHub offers a range of other features including form creation, automation and management, field-compliant eSignature services, and integrations.

DocHub also enables you to save time by creating form templates from documents that you utilize regularly. Additionally, you can take advantage of our a lot of integrations that allow you to connect our editor to your most utilized applications easily. Such a solution makes it quick and easy to work with your files without any delays.

DocHub is a helpful feature for individual and corporate use. Not only does it give a comprehensive suite of tools for form creation and editing, and eSignature integration, but it also has a range of features that prove useful for developing multi-level and streamlined workflows. Anything added to our editor is saved secure in accordance with leading field requirements that safeguard users' data.

Make DocHub your go-to option and streamline your form-based workflows easily!

because we donamp;#39;t quite have one for every single room in the house I decided to make my wife yet another cutting board I really wanted this one to be a high quality and durable piece so I decided to make it a walnut engrain board and the slab of Walnut that I had was sporting some dry Rod so I figured Iamp;#39;d try to salvage as much material as I could and just work around it and then to Jazz it up a bit I figured a contrasting inlay would look pretty sharp also so Iamp;#39;ll work in another neat feature into the bottom which I think will make using the board even easier well here we go letamp;#39;s get started after getting the chunk of slab cut off the first step was to flatten one side over on the Joiner with that done I could then reference that edge on the table saw and begin to cut the slab into strips now with this piece being more than 2 in thick I had to take several pass while raising the blade between cuts this was to avoid overheating the blade burning