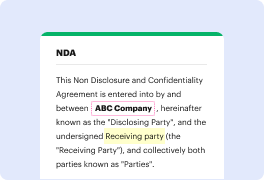

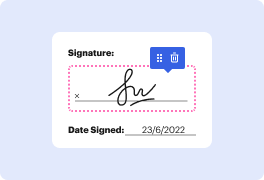

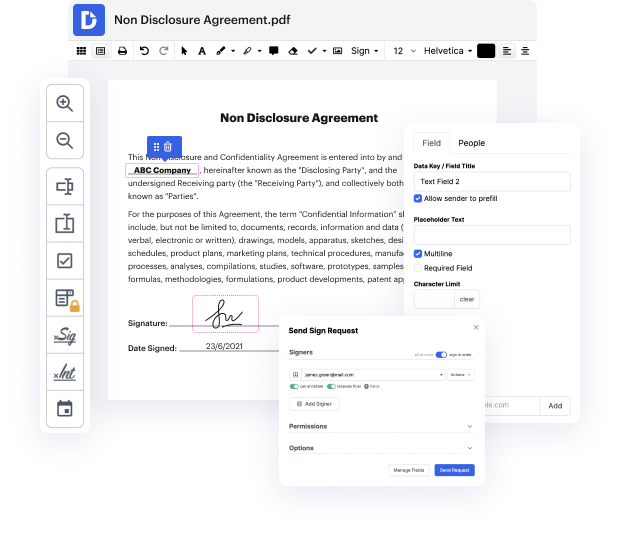

LWP may not always be the best with which to work. Even though many editing features are out there, not all offer a straightforward tool. We created DocHub to make editing effortless, no matter the file format. With DocHub, you can quickly and effortlessly inlay name in LWP. In addition to that, DocHub gives an array of additional tools such as form creation, automation and management, industry-compliant eSignature tools, and integrations.

DocHub also helps you save time by producing form templates from documents that you utilize regularly. In addition to that, you can benefit from our a wide range of integrations that allow you to connect our editor to your most used programs easily. Such a tool makes it quick and easy to work with your documents without any slowdowns.

DocHub is a handy feature for personal and corporate use. Not only does it offer a extensive set of tools for form creation and editing, and eSignature integration, but it also has an array of features that prove useful for producing complex and streamlined workflows. Anything uploaded to our editor is stored safe according to leading field standards that protect users' information.

Make DocHub your go-to option and streamline your form-based workflows easily!

have you been wanting to learn how to create inlays with your CNC router then youamp;#39;ve come to the right video because I am going to teach you exactly how to do inlays from the beginning to the very end and Iamp;#39;m going to take you step by step through the entire process and by the time youamp;#39;re done you will watch your own amazing inlay CNC router project come to life just like youamp;#39;re watching here youamp;#39;re going to learn actually how easy it is to create an inlay and how perfect you can get them so long as you follow a few simple specific steps which you are going to get in this video what Iamp;#39;m going to do with you is we are going to find the design in this case the feather and then weamp;#39;re going to actually design up the inlay for the insert and for the base piece and then weamp;#39;re going to run out tool paths and then you and I are going to run it out on our longmill CNC router Iamp;#39;m going to teach you how to take two raw pieces