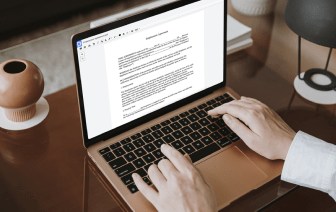

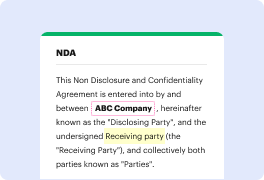

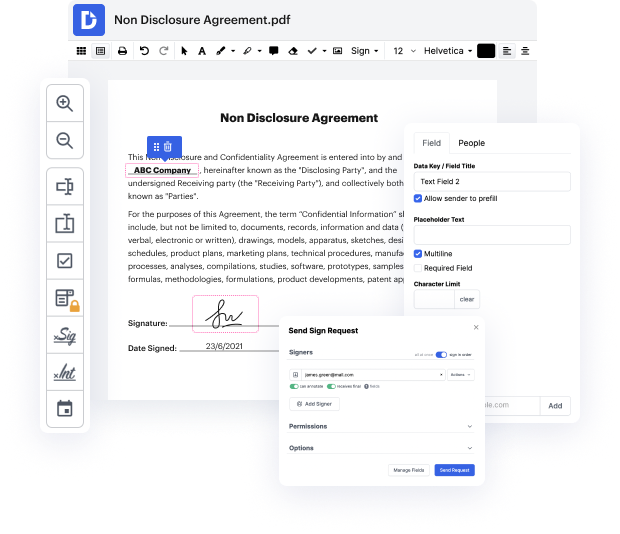

LWP may not always be the easiest with which to work. Even though many editing features are available on the market, not all give a easy tool. We created DocHub to make editing effortless, no matter the file format. With DocHub, you can quickly and effortlessly inlay character in LWP. Additionally, DocHub gives a variety of other functionality including form generation, automation and management, sector-compliant eSignature tools, and integrations.

DocHub also enables you to save effort by producing form templates from paperwork that you utilize frequently. Additionally, you can make the most of our a wide range of integrations that enable you to connect our editor to your most used apps with ease. Such a tool makes it quick and easy to work with your files without any delays.

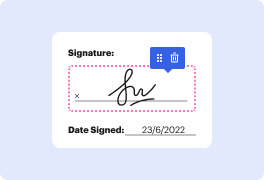

DocHub is a helpful tool for personal and corporate use. Not only does it give a all-encompassing collection of capabilities for form creation and editing, and eSignature integration, but it also has a variety of features that come in handy for producing complex and simple workflows. Anything imported to our editor is kept safe according to major industry requirements that protect users' information.

Make DocHub your go-to choice and streamline your form-based workflows with ease!

today there you going and welcome to my workshop so today weamp;#39;re going to do something a little bit complex what weamp;#39;re actually going to do is weamp;#39;re going to make an inlay with a laser so that means weamp;#39;re gonna actually cut the pieces out like this and then etch out a negative in a piece of oak and lay it in machining often see if we can make a perfect inlay you come in you can make inlays with it CNC routers quite successfully but you canamp;#39;t get my sharp corners with it really not with an end mill so we do it with a laser so what we need to do is find out the settings of the laser to be able to first of all cut this out perfectly and then etch out a negative in oak and this material is one-point-five just a little bit over 1.5 millimeters which is 61 fell alright for those of you who work in thousandths of an inch or inches so we need to work out with a test subject a test part how much power speed we need to be able to machine that out of