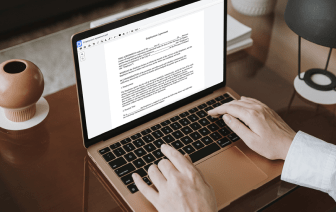

Document generation and approval are a central priority of each firm. Whether dealing with sizeable bulks of files or a specific agreement, you need to remain at the top of your productivity. Getting a excellent online platform that tackles your most frequentl file generation and approval problems may result in a lot of work. Numerous online platforms offer just a restricted set of modifying and signature capabilities, some of which could be valuable to deal with 602 file format. A solution that deals with any file format and task will be a superior option when selecting software.

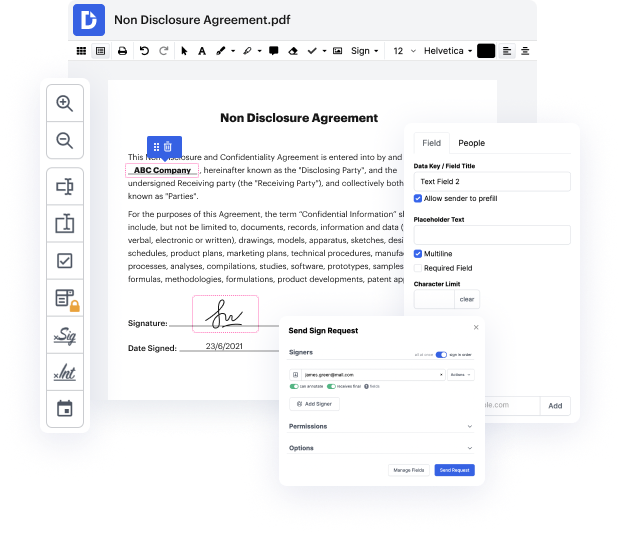

Take document administration and generation to another level of efficiency and excellence without choosing an cumbersome program interface or pricey subscription plan. DocHub provides you with tools and features to deal successfully with all document types, including 602, and perform tasks of any complexity. Edit, organize, and make reusable fillable forms without effort. Get total freedom and flexibility to enter engraving in 602 at any moment and securely store all your complete documents in your user profile or one of many possible incorporated cloud storage space platforms.

DocHub offers loss-free editing, signature collection, and 602 administration on a professional levels. You do not have to go through tedious tutorials and spend countless hours finding out the application. Make top-tier safe document editing an ordinary practice for the every day workflows.

[Music] foreign [Music] hey guys thanks for clicking today Im going to engrave names on the top of these leather boxes so the first thing I did was to measure the height of the Box this measurement came out to just under two inches and glow 4 states that two inches is the maximum height for Engraving and this will have to be done from the base of the glowforge with the crumb tray out next I want to make a placement jig out of scrap material so that I can easily place all the boxes in the same place I want this placement jig to be in the center of the base right under the camera so I place the scrap piece on the base of the glow Forge and I push it up against the front wall this will ensure that it will be square to the print head I then make minor adjustments and when its centered I tape down both ends with Gorilla Tape to lock it in place I then get my first box and I place it in The Jig and I push it into place I then decide to turn the box upside down and do a test engrave on the