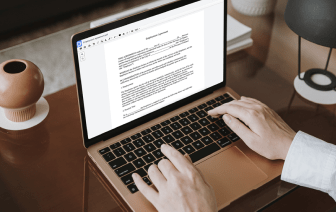

Searching for a professional tool that handles particular formats can be time-consuming. Regardless of the huge number of online editors available, not all of them support FTM format, and certainly not all allow you to make adjustments to your files. To make matters worse, not all of them give you the security you need to protect your devices and documentation. DocHub is a great answer to these challenges.

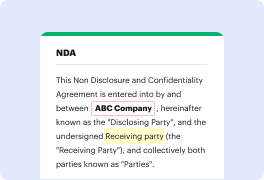

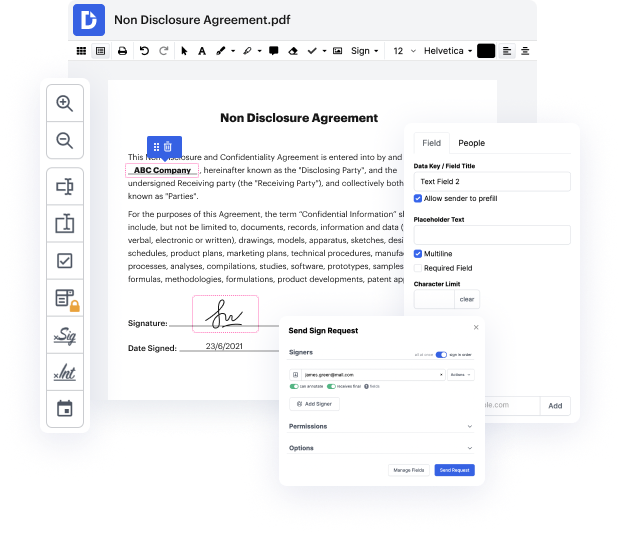

DocHub is a well-known online solution that covers all of your document editing requirements and safeguards your work with enterprise-level data protection. It works with various formats, including FTM, and helps you modify such documents quickly and easily with a rich and intuitive interface. Our tool fulfills crucial security standards, like GDPR, CCPA, PCI DSS, and Google Security Assessment, and keeps improving its compliance to guarantee the best user experience. With everything it provides, DocHub is the most trustworthy way to Embed seal in FTM file and manage all of your personal and business documentation, irrespective of how sensitive it is.

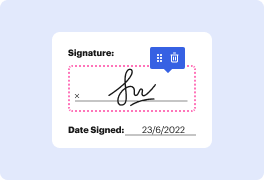

Once you complete all of your modifications, you can set a password on your edited FTM to ensure that only authorized recipients can work with it. You can also save your paperwork with a detailed Audit Trail to find out who made what changes and at what time. Choose DocHub for any documentation that you need to edit safely. Subscribe now!

before assembly the seal must be closely inspected for the following defects no damage on the circumference of the ceiling lip or the outer diameter check that the pre-tensioning element has no flash or damage any damage disqualifies a new seal from use never reinstall a used seal or a pre-tensioning element because there may be defects or geometrical changes you cant see this will result in a loss of retention or cause the seal to fail beyond the seal itself the grooves must be carefully examined the bottom walls and edges of the grooves must be free of damage such as burrs and nicks the surfaces and dimensions of the grooves and the rod should be finished ing to Trelleborg seeding solution specifications sea surface specifications in the app and groove dimensions in the hydraulic seals linear catalog or on the Trelleborg sealing solutions homepage assembly tools must not have any sharp edges and should be routinely inspected to make sure they have no burrs or scratches calibration c