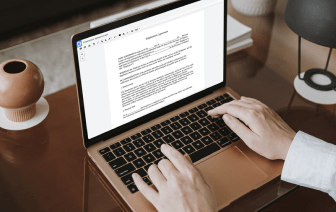

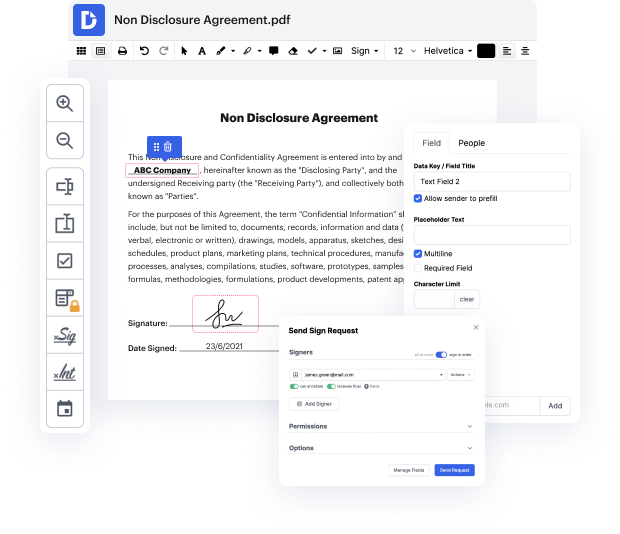

No matter how labor-intensive and challenging to edit your documents are, DocHub offers a simple way to change them. You can alter any part in your Sxw without extra resources. Whether you need to modify a single component or the entire document, you can rely on our robust tool for quick and quality outcomes.

Moreover, it makes sure that the output form is always ready to use so that you’ll be able to get on with your tasks without any delays. Our extensive group of capabilities also includes pro productivity tools and a library of templates, enabling you to take full advantage of your workflows without the need of wasting time on recurring operations. Moreover, you can gain access to your documents from any device and incorporate DocHub with other solutions.

DocHub can take care of any of your document management operations. With a great deal of capabilities, you can create and export papers however you want. Everything you export to DocHub’s editor will be stored securely as much time as you need, with strict protection and information safety protocols in place.

Experiment with DocHub today and make managing your paperwork simpler!

Hi everyone. Aaron here at Yeti Tool and in this video weamp;#39;re going to look at the key aspects of CNC cutting strategy. So what is cutting strategy? Itamp;#39;s the cutting methods and values you use for essential parameters. Setting your cutting strategy is done as you create your job file in your CAM software. For this video weamp;#39;re going to be using Vectric VCarve Pro. Understanding cutting strategy can be the key to taking your CNC work to the next level. Poor strategy can lead to all sorts of problems such as broken cutters, poor finish, inaccuracies, burnt materials, and damage to both your stock material and your spindle. We know it might seem daunting at first but by the end of this video youamp;#39;ll understand that the underlying concepts are very simple and for the common materials weamp;#39;ve already done the research on what values to enter. So please do check out our material profiles database on our Knowledge Base. We