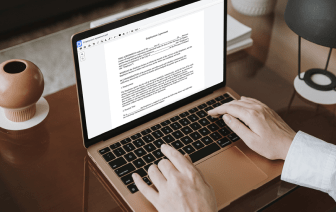

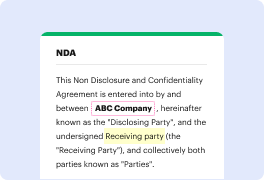

Unusual file formats in your day-to-day papers management and editing processes can create immediate confusion over how to edit them. You might need more than pre-installed computer software for effective and fast file editing. If you need to cut label in UOML or make any other simple change in your file, choose a document editor that has the features for you to deal with ease. To deal with all of the formats, including UOML, opting for an editor that works properly with all kinds of documents will be your best option.

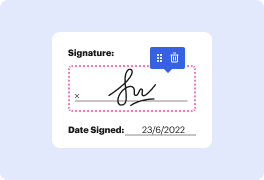

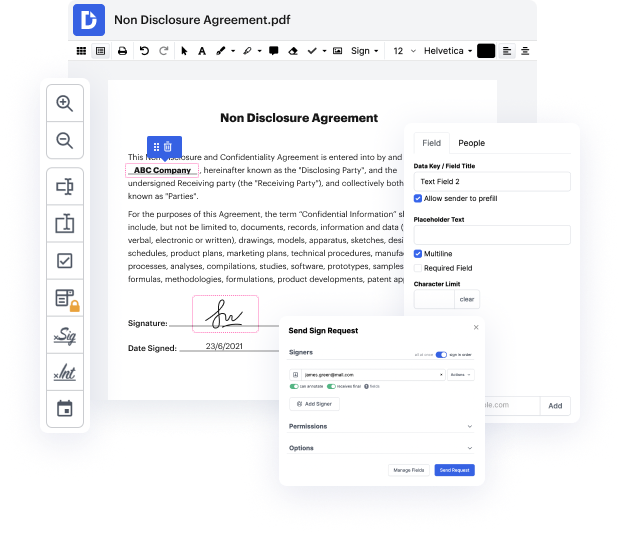

Try DocHub for efficient file management, regardless of your document’s format. It has powerful online editing instruments that streamline your papers management operations. It is easy to create, edit, annotate, and share any papers, as all you need to gain access these characteristics is an internet connection and an functioning DocHub account. Just one document solution is all you need. Don’t waste time switching between different programs for different documents.

Enjoy the efficiency of working with an instrument designed specifically to streamline papers processing. See how straightforward it is to modify any file, even if it is the very first time you have worked with its format. Sign up an account now and enhance your entire working process.

Hello everyone, and welcome to the second half of Showtime. Now, Im sure all of you are familiar with this material right here, the stubborn in-mold film. Its thinner than a hair. And difficult for many to master, understandably. Heidelberg has developed a process to carry out in-mold printing not only safely, but also at full speed. You can now see exactly how this works, and what role aerodynamics plays here. What we have here is our Speedmaster XL 106, 8-color with coater, and 3 Y-units. This press is specially configured for IML label printing as well as for wet-glue label printing. My name is Jochen Pecht. I work for the sheetfed label department as a product manager at Heidelberger Druckmaschinen. We have more productive components inside this press. We have a higher end speed. We can achieve a maximum of 14,000 sheets per hour, and at the end of the day we count a higher number of sheets on the printers pallet. Aerodynamics are a key component. My name is Peter Hachman