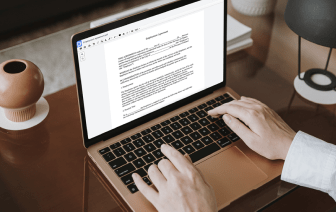

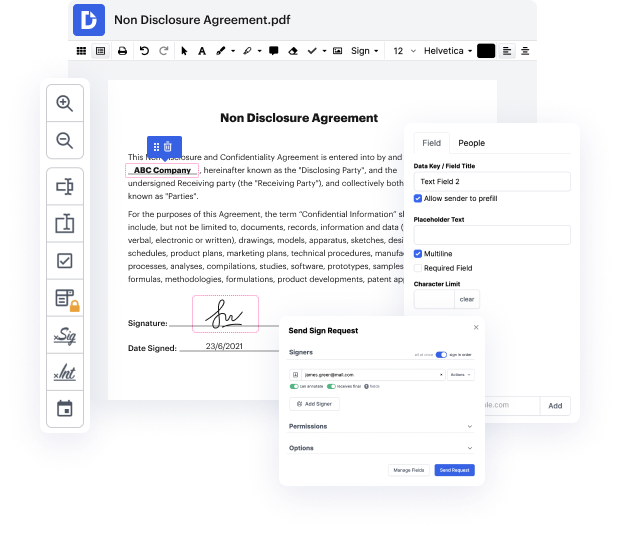

The challenge to manage paper can consume your time and overwhelm you. But no more - DocHub is here to take the hard work out of modifying and completing your paperwork. You can forget about spending hours editing, signing, and organizing paperwork and worrying about data protection. Our platform offers industry-leading data protection measures, so you don’t have to think twice about trusting us with your privat info.

DocHub supports various data file formats and is available across multiple platforms.

Paper production begins with wood arriving at the mill, primarily composed of 65% maple, 25% birch, and 10% poplar, requiring two tons of wood for one ton of paste. The process starts with a debarking drum, which removes bark from the logs in about 20 minutes; the bark is then burned to generate steam for mill operations. After debarking, logs are transported via conveyor and reduced to small pieces called kindling, with approximately 30,000 tons accumulated outdoors. The next step involves washing the kindling, followed by alkaline cooking, which is controlled through a diagram to ensure proper processing.