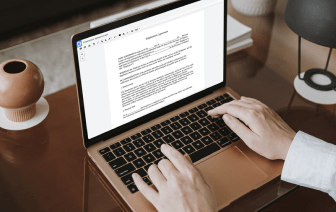

It is usually difficult to find a platform that may cover all your business demands or provides you with correct tools to control document creation and approval. Opting for a software or platform that includes essential document creation tools that streamline any process you have in mind is critical. Even though the most in-demand file format to use is PDF, you need a comprehensive software to manage any available file format, such as DITA.

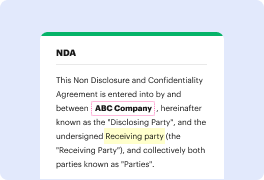

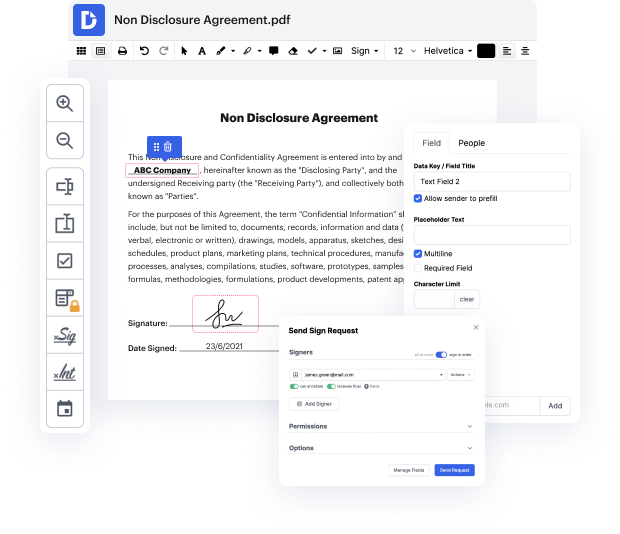

DocHub helps to ensure that all your document creation requirements are covered. Revise, eSign, rotate and merge your pages in accordance with your needs with a mouse click. Work with all formats, such as DITA, efficiently and quick. Regardless of the file format you start working with, it is possible to transform it into a required file format. Preserve tons of time requesting or looking for the correct document format.

With DocHub, you don’t require more time to get comfortable with our user interface and editing process. DocHub is surely an easy-to-use and user-friendly platform for anybody, even all those with no tech education. Onboard your team and departments and change document managing for your company forever. change engraving in DITA, generate fillable forms, eSign your documents, and get processes finished with DocHub.

Benefit from DocHub’s comprehensive feature list and rapidly work with any document in any file format, which includes DITA. Save your time cobbling together third-party solutions and stay with an all-in-one platform to enhance your day-to-day processes. Start your free DocHub trial right now.

hi guys this is that Poundland engraving tool I bought a little while back cost me a pound just going to take it apart for Steve Watts because he asked a question about the motor in it so oh thats it comes with a spare bit he was wondering whether you could use the this bit as a ball joint for a radio-controlled car Im not quite sure how but I can see the possibility obviously this is coated with some sort of abrasive but it is a little ball so you might get some sort of emotion out of it theres a possibility there I suppose you clamp it into a bit of brass tubing or something anyway well that was one of his points lets do the disassembly so to take it apart to a step pull it apart rather like this thats the batteries so the springy bit makes contact with the negative end and then the positive end goes in there and if I push this like that it falls in that little push button just sits in that hole theres nothing to stop it falling out other than the motor so if you get your fing