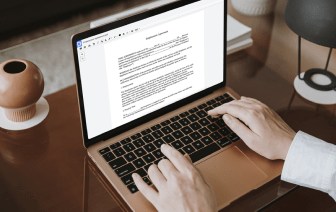

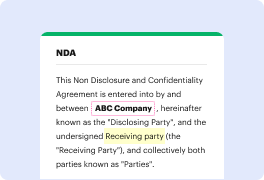

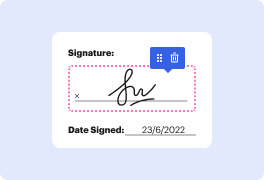

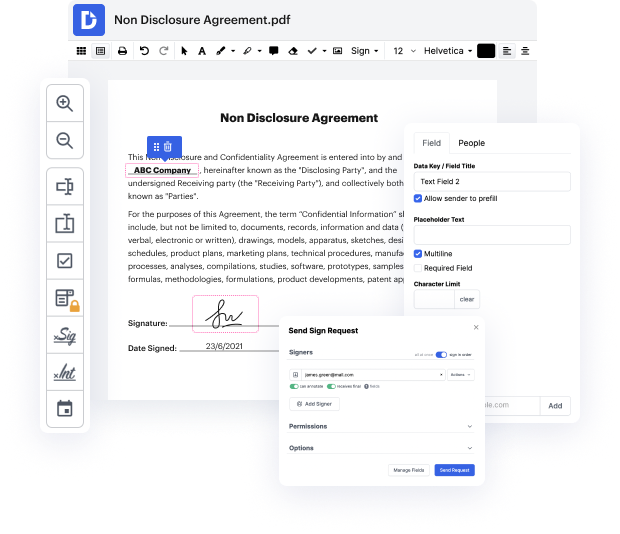

LOG may not always be the simplest with which to work. Even though many editing capabilities are out there, not all offer a simple solution. We designed DocHub to make editing easy, no matter the document format. With DocHub, you can quickly and effortlessly bind pecularity in LOG. On top of that, DocHub gives a variety of other functionality such as form generation, automation and management, field-compliant eSignature tools, and integrations.

DocHub also enables you to save time by producing form templates from documents that you utilize frequently. On top of that, you can make the most of our numerous integrations that allow you to connect our editor to your most utilized apps easily. Such a solution makes it fast and simple to work with your documents without any delays.

DocHub is a helpful feature for individual and corporate use. Not only does it offer a comprehensive suite of tools for form generation and editing, and eSignature implementation, but it also has a variety of capabilities that prove useful for developing multi-level and straightforward workflows. Anything imported to our editor is stored secure in accordance with leading industry requirements that protect users' information.

Make DocHub your go-to option and streamline your form-driven workflows easily!

this tool known as a graml is available from LMI it is used for marking or scoring binding and perfing channels on instruments like guitars violins and mandolins using this tool prior to using a router to cut The Binding or perfing channels will help reduce tear out in soundboard materials like Spruce and Cedar it can also be used together with a chisel to manually cut binding and purfling channels the radius part of the tool is used for working in rounded areas like in the waist on a guitar the flat part of the tool can be used for Less pronounced curves and flat surfaces the first thing you need to do when receiving your grandl from LMI is hone the blade so use the Allen tool provided with the tool and remove the blade just like when sharpening your other woodworking tools you need to flatten the back of the blade Iamp;#39;m going to use a 220 grit water stone to do this Iamp;#39;m then going to polish it up to a mirror finish on 1,000 4,000 and 8,000 grit once the back of the tool