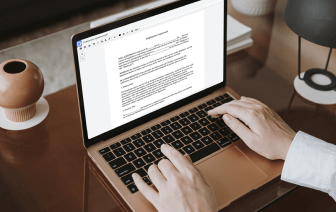

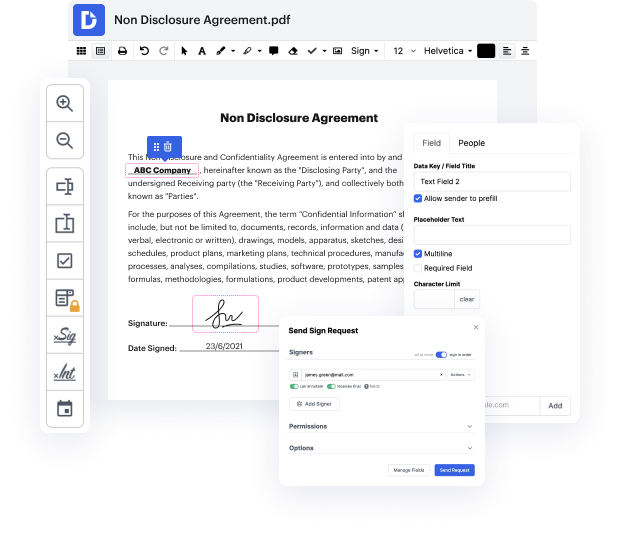

Today’s document management market is enormous, so finding a suitable solution satisfying your needs and your price-quality expectations can be time-consuming and burdensome. There’s no need to spend time browsing the web looking for a versatile yet simple-to-use editor to Adjust seal in WRF file. DocHub is here to help you whenever you need it.

DocHub is a globally-known online document editor trusted by millions. It can fulfill almost any user’s demand and meets all required security and compliance certifications to ensure your data is well protected while modifying your WRF file. Considering its powerful and straightforward interface offered at an affordable price, DocHub is one of the best choices out there for optimized document management.

DocHub offers many other capabilities for efficient form editing. For example, you can convert your form into a re-usable template after editing or create a template from scratch. Explore all of DocHub’s features now!

The right combination of heat time and pressure is required to produce quality seals on form fill seal Baggers and flow wrappers. These essential sealing elements are closely linked adjusting one can change the others and cause unexpected problems. This Greener Tech Bite reviews the function of and relationships between heat time and pressure, so you can better understand and anticipate the full effects of your adjustments. The function of heat is to melt the sealant layer of the packaging film and bond the film together. The makeup of the film dictates the required heat levels which should remain consistent across the ceiling jaw face to produce an even, secure bond. Time, often referred to as dwell, is the duration that the sealing jaws remain in contact with the packaging film. To produce a quality bond the sealing jaws and film must remain in contact long enough for adequate heat to penetrate through to and melt the sealant layer. Pressure is the force